There was a battle brewing in the 1980s and early 1990s that would eventually lead to IndyCar racing tearing itself apart, from which many changes resulted. One unintended consequence was a remarkable race engine.

In one corner was CART, an acronym for Championship Auto Racing Teams, the group formed by team owners who believed they could do a better job promoting Indy car races than the current establishment. In the other corner were USAC (United States Auto Club) and the Indianapolis Motor Speedway. Though each had separate goals they aligned in this battle. USAC didn’t want to lose control of the premier open-wheel series in North America while the Speedway didn’t want to be dictated to by a bunch of car owners. After all, they were the Indianapolis Motor Speedway, which operated one of the greatest races in the world – the Indianapolis 500.

For the 1979 season CART wrangled away from USAC some of the top oval races and soon added to the schedule permanent road courses. This came at a time when USAC was attempting to advantage the traditional American-made Offenhauser inline four cylinder over the more modern English-designed V8 Cosworth DFX.

USAC also watched in dismay as race car production swung away from American builders and to British builders and subcontractors. On top of that, the starting grids were starting to be filled by road racers, American and overseas drivers, with fewer seats going to Sprint Car drivers. In their eyes, the Great American Race was looking less American each year.

After a brief truce in 1980, leading to a joint operating board between CART and USAC brokered by the Speedway, the track’s management then forced USAC out of the partnership, ending their history of sanctioning Championship-caliber open-wheel racing, except for the Indy 500.

Both USAC and the Speedway believed that to bring American spirit back to the race that US OEMs and independent engine builders of those US-made powerplants needed to have greater involvement in the race.

The first step was for USAC to allow turbocharged stock block engines of up to 3.43 L boost levels of 55 inches (40 inches greater than atmospheric pressure). CART allowed the same displacement but at a lower boost level of 45 inches. The difference is significant as every 15 psi of boost essentially doubles the displacement of the engine. Buick and Chevrolet both developed turbo stock blocks for the 500, as not only was it the race with the greatest chance of success, but it was a race that carried an avalanche of publicity.

While fast, these stock block engines were fragile. In 1991, stock block representatives approached USAC with the idea of allowing them to produce tougher, race-quality engine blocks and other components, essentially throwing away the stock block rules, except for requiring a single camshaft, two valves per cylinder and pushrods. No doubt they thought they’d have an insurmountable advantage at the 500.

Fade out and reopen on a scene inside a restaurant in Phoenix, June 1993.

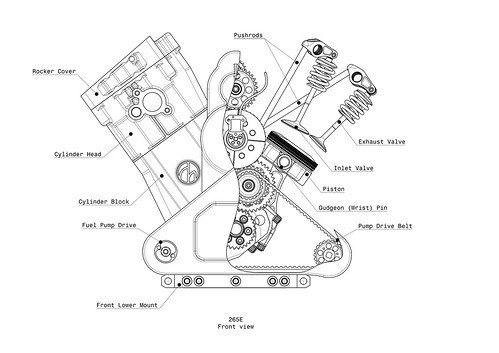

At the table were famed Indy car owner Roger Penske and his business partners and engine suppliers Paul Morgan and Mario Illien of Ilmor. Roger had been thinking about a specially-designed engine that met the rules to run the larger displacement and increased boost. He asked Illien whether such an engine could be competitive and Illien promised not only 940 HP but an engine the same length as their regular 265D DOHC engine, so it would fit into the new PC23 chassis without a great deal of additional development. Design work commenced in July of 1994 under the project number 265E to help obfuscate the project’s true nature.

Initially, Penske footed the bill for the engine’s development. Then Mercedes, another Penske partner, was invited to participate, added more money to the pot and gave the engine the designation of Mercedes 500i.

Secrecy was the utmost concern. Fears that other teams might catch on and build their own dedicated engines were rampant. So was the possibility that the engine could be outlawed before it ever turned a wheel at the Speedway, as USAC had done to the Chrysler Hemi in 1953. Ilmor used nonsensical part numbers as they shipped out work to nearby machining specialists. Penske created a remote shop, away from his regular crew, where work on the 500i could be completed in secrecy. It was taken so far that the 500i team worked all night and disappeared by 7 am so as not to interact with the regular crew.

What Ilmor created continues to be viewed with complete awe. The 500i was a 72-degree V8 with a central camshaft mounted high in the block to shorten pushrods as much as possible. Heads and block were cast from aluminum (the Buick continued to use cast iron blocks).

Novel followers were developed so that the canted valves could be positioned in the most effective location in the combustion chamber. Valves were 52.5 mm on the intake side, 39.7 for exhaust, all machined from titanium. The crankshaft was an 180-degree flat plane design with five main bearings and four counterweight. Each counterweight featured a tungsten insert to decrease the size of the crank. Bore was set at 97 mm with stroke at 58 mm, giving the engine an extremely oversquare ratio of 0.6. Compression ratio was 11.0:1.

The engine’s performance exceeded initial predictions, generating 1024 HP at 9800 RPM. That was a 200 horsepower advantage over competitors and if needed the 500i could be revved to 10.500 rpm. And the 500i weighed just 273 lbs. dry.

There were some early concerns regarding engine durability. While the 500i ran perfectly on the dyno, early track testing resulted in several broken wrist pins. The concern soon disappeared when it was calculated that running the engine in below-freezing conditions generated greater boast and the engine produced more power than which it had been designed. Testing in more typical conditions saw the wrist pin problems disappear.

The results of the 1994 500 were as expected. The two 500i Penskes sat on the front row and dominated the race, Fittipaldi and Unser lapping the field within the first hundred miles. Paul Tracy went out early, Fittipaldi collided with the turn four wall, so Al Unser Jr took the checkered with only one other car on the lead lap. As Penske, Mercedes, and Ilmor had expected, the engine rules were changed pretty much right after the race.

On June 13, 1994, USAC announced that the turbo boost of the purpose-designed pushrod engines was reduced from 55 to 52 inches. Ilmor fiddled with the engine’s parameters a bit and tested the 500i under those conditions. Ilmor determined the engine would remain competitive, losing only 60 HP of its 200 HP advantage. Then on August 10th USAC officials announced that there would be a further reduction to the maximum boost level for the purpose-design pushrod, now at 48 inches.

While still giving the 500i an advantage over fast-evolving four-cam V8s like that from Honda, was it worth the cost to a team to run two completely different engines over a season? So in reality, the remarkable Mercedes 500i was not banned outright or outlawed from Indy racing and the 500 as many believe, but rather the engine was squeezed out of relevance by USAC rules makers.

The fact that Penske and Ilmor had invested in 30 more engines for 1995 when the second rule change came down really lit Penske’s fuse. It was on the verge of the formation of the Indy Racing League, for which he had no patience. But it was Penske who had the last laugh as he purchased IndyCar Series (essentially IRL, rebranded) and the Speedway itself last fall.

I hope Roger Penske brings back “stock Block” racing to the Indianapolis 500, now that he owns the entire show! Go Roger! Open the door to an inventive atmosphere involving the auto companies of the world.

Yeah! and not to hybrid/electric.

Back in the day (1960’s/1970’s) it was always fun to see what kinds of equipment showed up each May.